Please notice: This article is more than 3 years old

Content, Source code or links may no longer be correct in the meantime.

November 21, 2021 | 14:00Reading-Time: ca. 4 Min

Digitalisation out of hell

10 years ago, the buzzword and digitalisation project “Industry 4.0” first emerged with nothing less in mind than the intention of unleashing a fourth industrial revolution.1 Revolution as a term and metaphor is, of course, nonsense. Anyone with the slightest sense in the matter knows that digitalisation is rather like a marathon with many intermediate stages and does not come overnight to a company as a result of a management decree.

However, there is nothing wrong with the objectives of networked communication, information transparency, technological assistance and decentralisation. I actually welcome these objectives and would like to extend this list to “digital sovereignty”2.

When apart from buzzwords only total failures remain and barely about 10 % of the companies are successful in their Industry 4.0 projects according to a survey by CapGemini3, I dare to ask: Is it due to the strategy, the implementation, the people or all of the above?

Two real life examples to think about, of course based on personal experience and without claiming universal applicability:

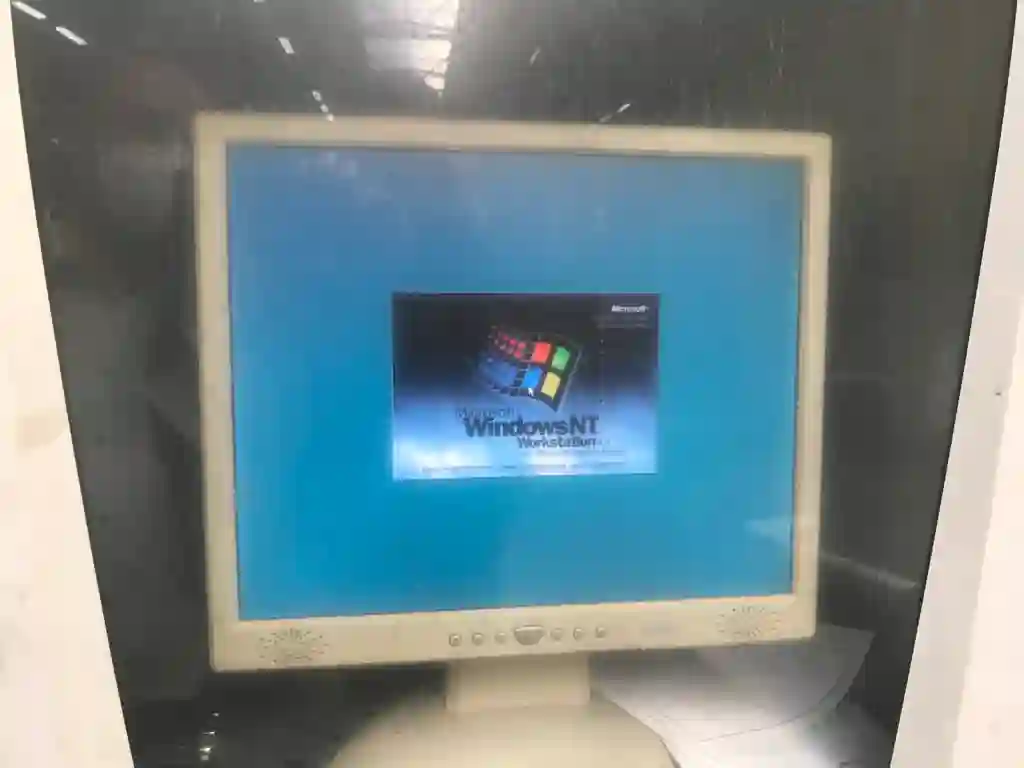

Industry (NT) 4.0

A fortnight ago, in the course of introducing an ISMS 4, I identified the oldest Windows computer in the inventory of a mid-sized company. With its 384 MB RAM, it reliably controls and visualises the processes and is part of a larger production line.

The system as a whole is technically sound, maximally efficient and has not only proven itself over the past decades but also left the typical infantile problems behind. For the specialists in the factory’s own maintenance department, there is hardly anything that cannot be repaired within a very short time. All components are standardised, easy to reach and the spare parts situation is quite acceptable.

The system is in its prime if there were not the rotten Windows NT4 Workstation5 and the closed-source management software. Like a dark shadow, they cast over the precious sensor values and the communication with an ERP and merchandise management system. Like a black box, it is not maintainable, not expandable and, thanks to proprietary programming and technologies, not easily portable to more up-to-date technology.

A good example of how closed-source software restricts digitalisation as well as advances whilst increasing complexity and costs elsewhere.

The idea of “autonomous” driving

Jump over to the automotive industry, which is undoubtedly in the midst of upheaval. Large manufacturers are pushing through the missed electrification and digitalisation. The results leave much to be desired, at least from the end customer’s perspective. Unfinished, overpriced and rarely thought-through solutions do not inspire confidence, at least not in me.

For example, during a test drive of an electric Volkswagen two years ago, I still encountered an “ignition key” in the display and manual. When I think of the Volkswagen automotive cloud with Azure6, I inevitably feel an impulse to vomit and cannot help but say “No, thanks”. Every time when a global corporation externalises its digitalisation, I see a desperate waving of a white flag.

If, at the end of the day, car buyers can no longer use their otherwise technically fully intact vehicle due to an app or server problem7, the product, including the product design, is immature and has nothing in common with the ideas of decentralisation, “autonomous driving” or “automotive freedom”.

Incompatible product life cycles

We are in the middle of a digitalisation that often has nothing to do with technology. Instead, the business basics are changing before our eyes. We are seeing the emergence of quantifiable iaccessnferior goods with questionable add-ons and sometimes inverted basic functions in place of durable and repairable goods.

Windows “operating system” as it exists today has been turned into an advertising, product and access platform, including tracking, against the user for some time now. With its multi-coloured start menu tiles full of advertising and product placements, it looks more like the AOL desktop access software used in the 1990s. Modern operating systems that offer their users maximum available resources and control look differently and are by the way open source. The examples can be applied to hardware, cars, industrial equipment, household appliances and many other goods and industries that take their cue from the broken concepts of an IT industry and adopt them unthinkingly.

I am cynical and claim that the smart promises of cost advantages or efficiency gains are bought with shortened product life cycles in the first approximation and leave risks from dependencies and technical debts8 unmentioned in the second approximation.

Sustainability goes differently. And so does digitalisation.

Operational excellence even more so.

With that in mind,

Tomas Jakobs

https://de.wikipedia.org/wiki/Digitale_Souver%C3%A4nit%C3%A4t ↩︎

https://www.capgemini.com/wp-content/uploads/2019/11/Report-%E2%80%93-Smart-Factories.pdf ↩︎

https://de.wikipedia.org/wiki/Information_Security_Management_System ↩︎

🚫 https://www.volkswagen.de/de/elektrofahrzeuge/elektromobilitaet-erleben/elektroauto-technologie/automotive-cloud.html ↩︎

https://www.spiegel.de/auto/mehrere-tesla-fahrer-nach-ausfall-der-app-ausgesperrt-a-cebdaab9-6f99-41b6-a752-48981285243b ↩︎